Technical information

live centers

Extraction thread and extraction nut

All live centers, except those of the GF series, are available as special versions with extraction nuts. The extraction nut arranged on the housing is used for ejecting the center from the tailstock.

Dimensions

The fitting tapers are manufactured according to DIN 228 AT4 and Greber company standard.

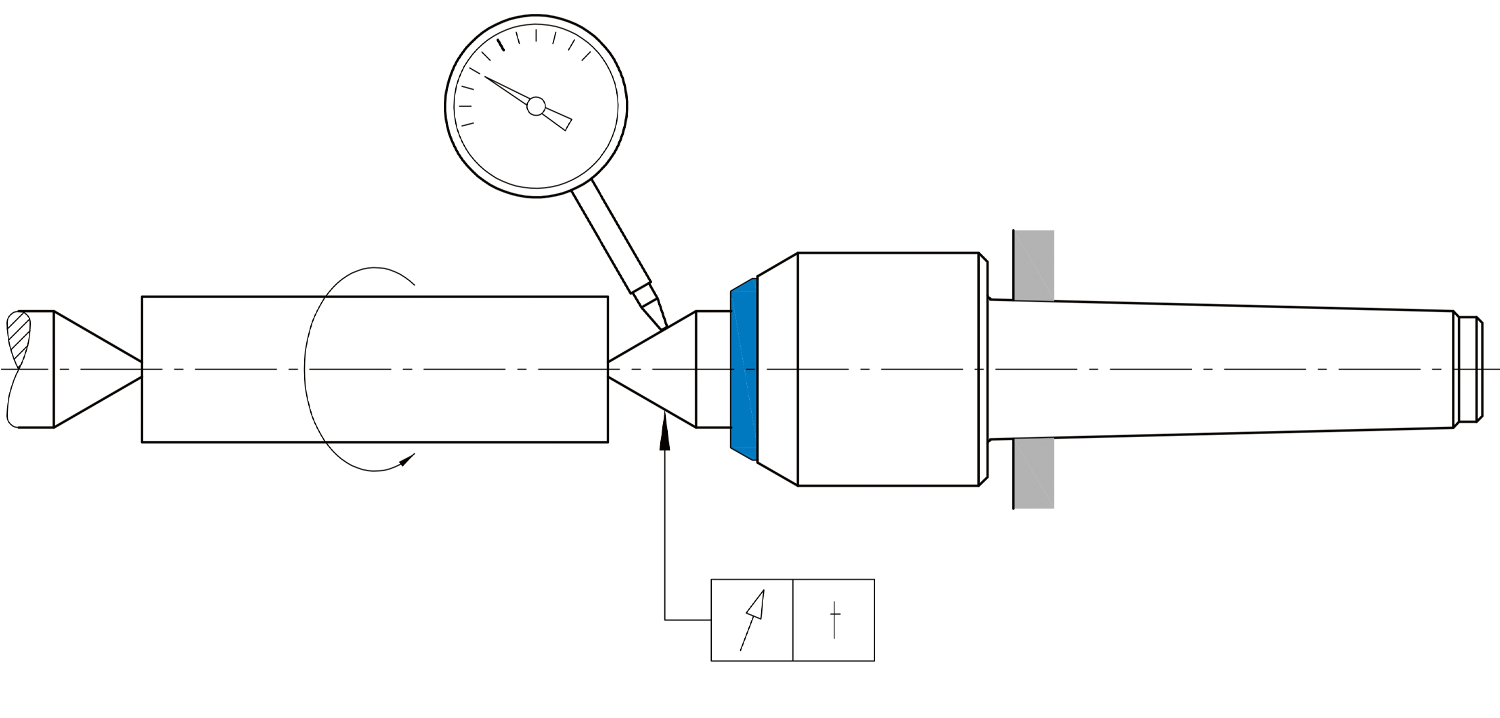

Concentricity

| Series | t standard mm | t high accuracy mm |

|---|---|---|

| C, R, D | ≤ 0.005 | – |

| T | ≤ 0.005 | – |

| X | ≤ 0.003 | ≤ 0.001 |

| P | ≤ 0.001 | – |

Loads

The weight indications for workpieces are based on the assumption that the workpieces are held between two live centers and therefore one has to hold maximum 50% of the workpiece weight. Additional loads, for example due to imbalance or due to uneven weight distribution, are not allowed.

IMPORTANT:

- Pay attention to the load diagram.

- Carbide tipped live centers, centers with interchangeable inserts and LK/LG centers may not be used with maximum load.

Maintenance

All live centers are permanently lubricated. Up to 2 000 hours without maintenance.

Dimensions of clamping cone

| Taper K | D |

|---|---|

| MK 2 | 17.78 |

| MK 3 | 23.825 |

| MK 4 | 31.267 |

| MK 5 | 44.399 |

| MK 6 | 63.348 |

| MK 7 | 83.061 |

*Availability legend: ● ex stock ● 2–3 weeks ● 6 weeks / on request

Subject to technical alterations